Our Smart Factory is a revolutionary all-in-one solution, that addresses manufacturers' challenges in one

place.

From meticulous production planning to seamless product delivery, our products help

to streamline every

aspect, ensuring an efficient and unified manufacturing journey.

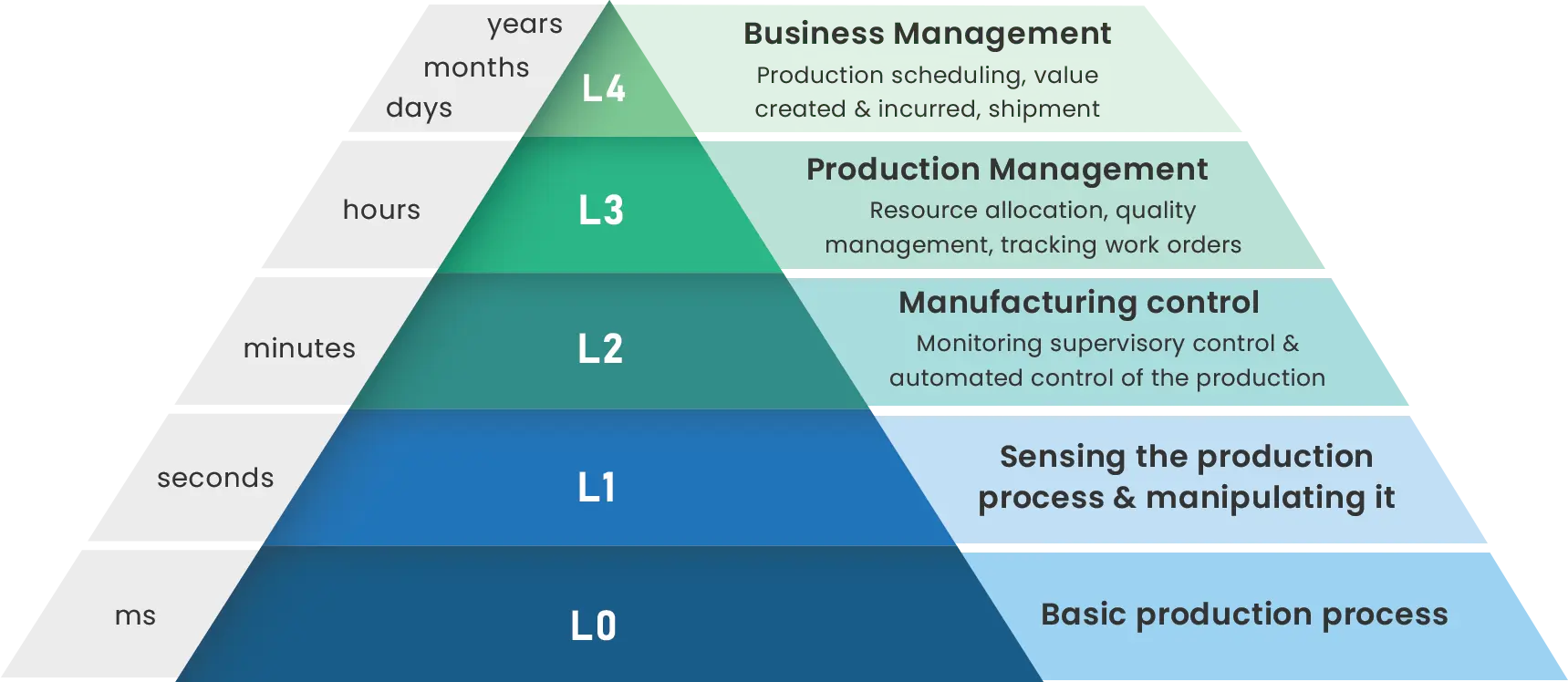

Our Smart Factory is a revolutionary all-in-one solution, addressing manufacturers' challenges in one place. From meticulous production planning to seamless product delivery, our products help to streamline every aspect, ensuring an efficient and unified manufacturing journey.

Streamline production oversight with integrated quality control and Statistical Process Control (SPC) measures.

Attain uptime excellence with expert maintenance, ensuring seamless machine continuity and optimized reliability.

Maximize operational efficiency by seamlessly overseeing work-in-progress and materials in your manufacturing setup.

Optimize manufacturing sustainability through strategic raw material planning, minimizing waste, and maximizing resource efficiency.

Our smart factory solution is an all-in-one revolution, seamlessly integrating MES, MRP, and WIP Manager to

transform your

shop floor and boost productivity. Delve into the details of each Smart Factory module

now!

Manufacturers can gain clarity and enhance the efficiency of their production floor with our MES Solutions, offering real-time tracking and control of production processes. The system includes features such as inventory tracking , ensuring seamless management of stock levels, and providing transparency from procurement to production. MES enables precise production scheduling, optimizing workflow for timely and efficient manufacturing. The system also streamlines machine maintenance, minimizing downtime by ensuring equipment operates at peak efficiency. Additionally, MES Solutions offers product lifecycle traceability, allowing manufacturers to monitor a product's journey from inception to delivery.

Our tracking tool, WIP Manager, revolutionizes work-in-progress management by simplifying the production journey and providing manufacturers with a comprehensive view of ongoing tasks. WIP tracking is made seamless through WIP Manager, allowing manufacturers to effectively manage WIP, optimize resource allocation, and enhance planning and coordination. The tool generates detailed WIP reports, offering insights into the production process and enabling informed decision-making. With features designed to minimize rejection, rework, and scrap, WIP Manager contributes to a reduction in bottlenecks and idle time, ensuring that work moves seamlessly through each stage of production.

Our MRP software revolutionizes material management, ensuring that manufacturers have the right resources at the right time. The system excels in raw material tracking and oversees material stock through end-to-end inventory control. MRP optimizes inventory levels, preventing shortages and excesses while efficiently managing material movement. With a focus on raw material planning, the tool enables manufacturers to forecast material needs accurately, promoting smoother operations and the ability to meet demand. Therefore, manufacturers gain improved cost control with MRP by minimizing waste and avoiding overstock situations, ultimately maintaining a competitive edge in the market.

Let's get started!

Reach out to our team to explore the option that best suits your requirements